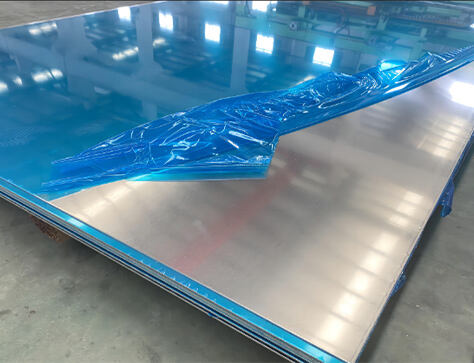

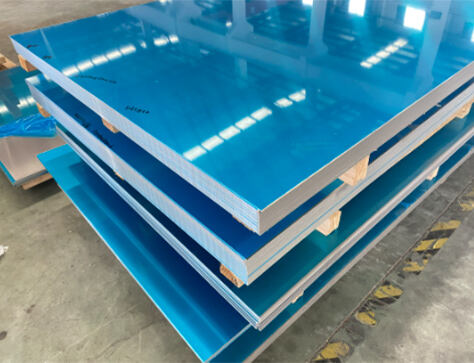

Aluminum plate sheet is a large, rectangual material that can be used for all manner of things such as vessels etc. With its lightweight, rust-free qualities it is easy to handle and move around; ideal for use outdoors in all weather conditions. In addition to this, it is also known as non-toxic and neither a magnetic property making it ideal for sanitation purpose in places like food processing or medical instruments.

Aside from these advantages, flat aluminum plate is virtually maintenance-free while other metals have to be cleaned and coated. This simplicity carries over into the realm of maintenance, adding value to its cost-effectiveness. Because it conducts heat and electricity well, aluminum also is used to make electrical wiring and devices2 that depend on heat sinks.

Advances in flat aluminum plate technology have sparked continual innovation of the manufacturing process, facilitating custom shapes and sizes for unique applications. Now, you just have to bend these plates yourself or do some perforation work on them in a particular design pattern and there it is aesthetic as well functional. Furthermore, the inclusion of computerized systems and robotic machinery under Big Data techniques has yielded low wastage figures with maximum functionality in every operation to generate uniform output.

When considering flat aluminum plate, even in the annealed state it is a relatively soft and ductile material that appreciates once minimally distrurbed can be predisposed to cracking or deformation/failure under excessive stress. They are fragile and easily broken, so transport etc. is important for not causing any accident. However, aluminum has high conductivity and coming in contact with wires or devices operating at live voltages can cause dangerous electrical shock and fire so it is IMPORTANT to take appropriate safety measures!

Due to its strength and resistance, flat aluminum plate finds extensive applications in construction as well as architecture industry where it serves for roofing, window frames,cladding or gutters. Its light nature makes it most commonly used in the transportation industry where you may find car body parts, aircraft fuselage or boat hulls. Additionally, the food processing and packaging industry leverages its non-toxic properties in cookware production; food containers & wrapping material etc. Flat aluminum plate is used in several other applications, including heat sinks for the electronics industry and various electrical wiring.

Proper storage of flat aluminum plate is extremely important, because only when the dry and ventilated environment without water vapor can make it better oxidation. When it comes to aluminum, the right tools and safety gear are essential to prevent a dangerous mishap. And flat aluminum plate is easy to clean and maintain with only a gentle wipe down using a mild detergent/water solution. Also, it is advisable to use a protective coating for added protection from corrosion specifically in locations where sea salt light can be found.

Innovation in aluminum plate technology has made it possible to manufacture customized shapes and sizes, depending on the desired application. Flat aluminum sheets can be bent, cut, or perforated in various patterns and designs to suit the desired aesthetic appeal or functional requirement.

Additionally, the manufacturing process of flat aluminum plate has been optimized to reduce wastage and improve efficiency. The use of computerized systems and robotic machines makes the process highly automated, leading to consistent and high-quality output.

Safety is critical when working with any metal material, and flat aluminum plate is no exception. In its raw form, aluminum is relatively soft and ductile, making it prone to cracking, deformation, or failure when subjected to excessive stress. Therefore, it is important to handle and transport it with care to avoid damaging it or causing injury.

Furthermore, aluminum is highly conductive, and any electrical contact may result in severe electrical shock or fire. Therefore, it is essential to take appropriate measures to prevent accidental contact with live electrical wires or devices.

4. Uses and Applications of Flat Aluminum Plate

-Construction and architecture: It is often used in roofing, cladding, gutters, and window frames due to its strength and weather-resistant properties.

-Transportation industry: It is commonly used in the manufacture of car body panels, aircraft fuselage, and boat hulls due to its lightweight nature.

-Food processing and packaging industry: It is used in the manufacture of cooking utensils, food containers, and wrapping material due to its non-toxic properties.

-Electronics industry: It is used in the manufacture of heat sinks, electrical wiring, and casings for electronic devices.

To ensure the longevity of flat aluminum plate, it is essential to store it in a dry and well-ventilated area, free from moisture and dust. When working with aluminum, it is crucial to use the appropriate tools and safety gear to prevent injury.

Aluminum is easy to clean and maintain, and a simple wipe down with a mild detergent and water solution should suffice. Additionally, to prevent corrosion, it is advisable to apply a protective coating, especially in areas exposed to harsh weather elements.

flat aluminum platestock most competitive prices because of our large and rich inventory, which significantly reduce delivery time and save customer's time.

precision testing equipment an experienced quality inspection team Each batch of flat aluminum platesubjected rigorous screening and testing make sure that quality meets the customers' specifications.

Quality testing a sales team from flat aluminum plateworld who more than 10 years' experience will provide with peace of assurance when make your buying decisions.

We can different product resources according customer's give you one-stop purchasing . flat aluminum plate processing centers meet customized needs of different customers.