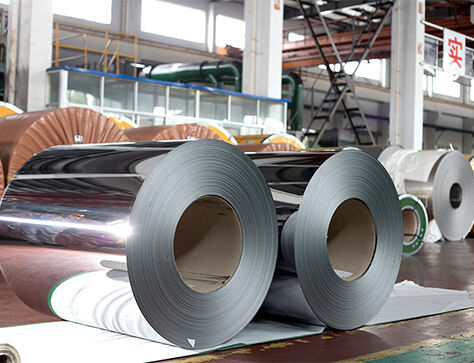

Galvanized iron, GI) steel coil is a strip or sheet which has been coated with zinc (zinc coating: 20 g/m2 to 15-300g /m2), produced by hot-dip galvanic process. Zinc provides a highly durable coating that is resistant to corrosion, making it an attractive option in the construction industry for applications such as roofing and wall paneling. Key manufacturers that are operating in global market of GI steel coil namely are ArcelorMittal, Nippon Steel,POSCO,Nucor Corporation and Baosteel. These companies have a long history of producing excellent products through unique manufacturing methods.

ArcelorMittal, the world's biggest steelmaker with about 5% of global output, is a heavyweight in the industry. These are the GI steel coil structures that have galvanized a few applications and serve wide needs. As one of the most advanced Japanese steelmaker, Nippon Steel is well-known for its top-quality products. More importantly, they are the manufacturer of Galvalume steel which is a specific type in GI metal coil with double Hot-dipped coating layer of alloyed aluminum & zinc. One of the major players in steel manufacturing from South Korea is POSCO which has a reputation for quality and innovation as far as GI Steel coil production is concerned. Nucor Corporation, one of the most distinguished American steelmakers produce different types of galvanized steel materials like GI coil that are actually made to fit building and automotive sectors. Moreover, the major Chinese steelmaker Baosteel is capable of producing outstanding GI steel coil as well as other types of steel that are known for industry leading quality and performance.

The GI steel coil is perfect for the construction industry considering all of its features that makes it best material to use in different applications. To begin with, its superior sturdiness and non-corrosive qualities render it a dependability alternative for open-air ventures including material For Mens fencing and siding. Additionally, its fire-resistant nature adds to the safety features in a building rendering it one of the most sought after choices for construction. Furthermore, GI steel coil is lightweight thereby making it less cumbersome to work with and carry around in construction projects. This wide versatility range is further enhanced by the availability of this material in various grades and thicknesses, which allows for applications from the most heavy-duty to light ones.

One of the major benefits that you add on making use of GI steel coil in manufacturing sector is it promotes environmental sustainability. Advancements in the steel industry have been commendable, with GI steel coil turning into one of the most environmentally friendly building materials to use today. And as both, it can be recycled time and again keeping the waste to a minimum and saving precious resources often used for their production even new plastics but due to its longevity that need not happen very frequently mooting attempts at long term sustainability.

Quality and integrity of GI steel coil can not be reached without proper storage, handling practices so potential damage hazards should always be kept in mind. GI steel coil should be stored in a dry, covered location to protect it from dampness and other outside factors that may result in deterioration. Besides, not storing the coil in a way that it touches some other materials prevents scratches or dents from happening. Inadequate support could cause the steel coil to bend or warp during storage.

GI Steel Coil is an item of great dimension and capacity so should not be carried without the help of equipment i.e. crane, truck or any machines you feel are suitable to lift it appropriately and carefully. Never drag the coil, as this will cause a damage to the edges and impact surface quality Play it safe and always jump into the project prepared, ready to use safety glasses or gloves while getting control over that coil. To maintain these surface finishes as well the sheet quality follows careful and gentle handling of steel coil.

Though GI steel coil is the most widely used construction material, there are many varieties of coated steel that fulfil different requirements in the industry. The commonly used stainless steel in the construction is due to its good corrosion resistance and beautiful appearance. But it may bring difficulty to a certain project for its higher cost and complexity in handling.

Cold-rolled steel: Somewhat of a specialized type, it is produced by rolling the steel at room temperature to achieve not only an out-of-the-world finish but also greatly machinability for use in appliances, furniture and high-end cars. In contrast, hot-rolled steel is processed at high temperatures for superior strength and most often used in the construction of larger structures such as buildings & bridges.

Courtesy: GI steel coilSteelmakers are changing how they make their products and driving more innovations in the industry to satisfy different needs. One of the notable trends is a growing emphasis on sustainability and environmental responsibility, which mandates steel manufacturers to adopt eco-friendly approaches and use recycled materials in their manufacturing processes. These include the advent of advanced coatings and finishes, such as Galvalume (a co-product of zinc at 55% or more with aluminum) & Galfan(a Zinc-Aluminum coating containing about 5% Aluminum), to provide enhanced levels resistance against elements that make GI steel coil usage suited for harsh environments.

In addition, more automation and robotics is used in steel production to improve both efficiency and cost. Using this technology, manufacturers can improve production outcomes and waste reduction while also producing high-grade products at affordable consumer prices.

To sum up, with those advancing and unique features GI steel coil has formed its own place in the construction industry that provide you corrosion resistance, fire safety along environmental sustainability. Proper storage and handling must be completed in order to maintain the quality of steel, while ensuring that you select the right type for each one will help. The production and application spotlight of the future (of GI steel coil) is on sustainability, advanced coatings as well as motifs that are up to date with technology that keeps changing within industries.

With most precise testing equipment professional quality inspectors Every batch products is subjected rigorous screening and testing to gi steel coilthat quality is in complete accordance with client's expectations.

Testing quality a sales team from around world with over ten years' experience give you peace assurance when make your buying gi steel coil.

You obtain first-hand gi steel coiland the lowest cost due our abundant large inventory. This significantly shorten delivery time well as save time of client.

We match product resources according needs and give one-stop purchasing experience.Professional processing centers the customized needs of different .