In every reach of manufacturing, Low Carbon Steel Sheet is a go-to material due to its reliability and practicality.

The low carbon steel sheet is a very common kind of metal and it used in most industries e.g., construction, manufacturing etc. It is versatile, durable and provides a wide range of benefits that sets it apart from other metals. This piece is the continuation of advantages, properties and various innovative as well as security functionalities for Low Carbon Steel Sheet it offers to different industry applications so go through our blog to know more about this that are trending nowadays.

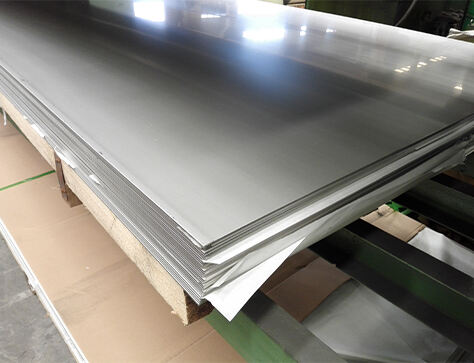

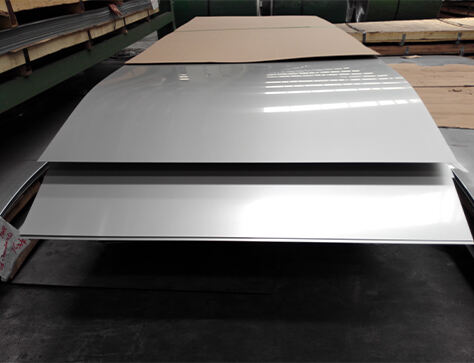

This high tensile strength, durability and ductility has made low carbon steel sheet the preferred choice of material for a countless metalworks. Cartridge bodies are corrosion resistant and sturdy at high temperatures as well as pressure. It is also readily weldable, bendable and formability which makes it a suitable material for numerous projects.

It has made low carbon steel sheet an innovative & safe choice for different industries due to the advance features around it. This is part of a newer type of manufacturing technique in which the sheets are produced through rolling-a process that results in thinner and better quality surfacesheets. Thin sheets like this are often used in applications where tight tolerances matter, such as automotive body panels and electronics.

In addition, safety precautions have made low carbon steel sheet to become a safe alternative for the workers. The material is noncombustible and does not generate toxic fumes or harmful radiation, so it can be used in installations where win sensitive environments. In addition, the low carbon build helps to none while continuously enhancing safety with less brittleness or cracking.

Uses of Low Carbon Steel SheetLow carbon steel sheet finds use in various industries such as construction, automotive and aerospace. It is used in the manufacturing of a vast range of products from domestic appliances to structural components. Also called mild steel putty plate, it s widely used in the construction of pipes and shipbuilding as well.

This is used in creating structural elements such as beams, columns and trusses for the construction industry. It is also essential in manufacturing steel building frames, bridges and other civil engineering projects. While in the automotive field, low carbon steel sheet is used for producing body panels and parts of aircrafts including bumpers and its various structural components.

Low Carbon Steel Sheet is easy to use, and therefore it can be used in various applications without complications. You can apply this to any thickness and size that you need by cutting it down or creating the desired shape. The sheet can be machined and fabricated using traditional methods of welding, bending or forming.

The use of gloves and eye protection is recommended in the event that workers have to handle low carbon steel sheet; this will help ensure their safety. It is essential for everyone who needs to be reacted towards the proceedings when it comes down to cutting, welding and shaping of such sheet using safety assignments.

can match different product resources according customer's needs give you -stop purchasing experience.Professional low carbon steel sheet the customized needs of different customers.

A quality testing international sales team has more ten years of experience. team will give peace of mind in low carbon steel sheetdecisions.

Every low carbon steel sheetof products is tested and examined by group of experts using precision testing equipment. This ensures that quality meets all requirements the customer.

low carbon steel sheetstock most competitive prices because of our large and rich inventory, which significantly reduce delivery time and save customer's time.