This article is going to show you some of the advantages offered by polished aluminum plate that allow it easy application in various industries.

As a property aluminum has portioned into many different fields and applied by industries of all sizes thanks to its strength, durability, along with low density. Though in some cases, aluminum needs to be treated with a shiny finish - lavish and corrosion-resistant conditions also preserving its stiffness. This is where the polished aluminum plate comes in.

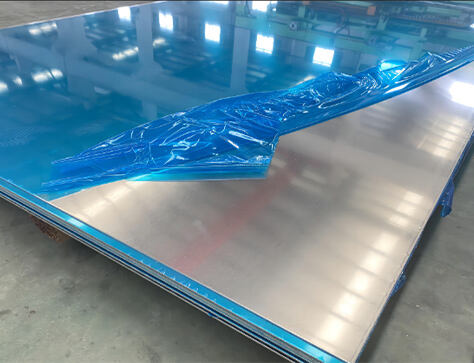

A polished aluminum plate is simply a flat aluminum sheet, which in turn has undergone one kind of specialized finishing treatment so that the outer surface becomes as bright as mirror. These abrasives tools and compounds are used in a intricate process which involves grinding, buffing, or polishing to remove all of the inconsistencies resulting with an high gloss "mirror-like" finish. This type of finish offers a number of benefits in many different industries- from industrial machinery to automotive components and aerospace parts. Below, we will explain why polished aluminum plates are the best solution for these industrial fields.

Aluminum plates are a reliable and cost-effective material used in many industrial applications to create machinery, especially conveyor systems or storage tanks amongst other equipment. Raw Aluminum - Raw aluminum has a dull and abrasive surface that tends to catch the dirt, grime and debris from within which subsequently may affect operational capabilities of equipment. The aluminum plate polishing creates a bright, semi-smooth finish and is designed to protect the metal against corrosion while providing an aesthetically pleasing effect.

In addition to the above, polished aluminum plates are able reflect light back into your work environment, creating a brighter space while also saving you from needing even more lights throughout your project area and thereby saving on energy costs. Finally, polished aluminum is more cleanable and maintainable than unpolished aluminum which can save you both time and labor in the future.

Getting a mirror finish on an aluminum plate requires equipment, knowledge and method It involves multiple steps, sanding/buff/polishing with different grits and compounds to desired level of smoothness or gloss. A lack of experience will generally result in too much heat or toplow in the metal, which is why using adequate tools and abrasives while applying consistent pressure without overdoing it should be enough not to injure yourself.

If you want a high-quality finished polished aluminum plate but do not have the resources or knowledge to do it yourself, you can hire metal finishing services. Using top notch equipment and molds, our experts are able to mirror finishes so your aluminum looks not just like steel but anything from a brass to copper or other metals. Moreover, they can customize the finishing to suit your design needs (whether color, texture imprint or logo).

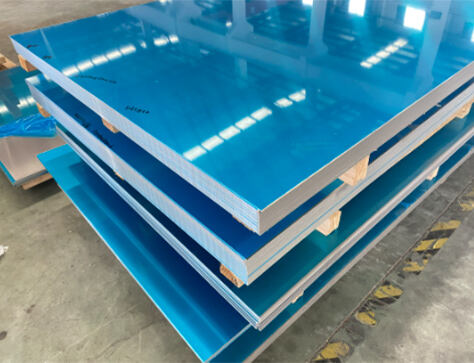

precision testing equipment an experienced quality inspection team Each batch of polished aluminum platesubjected rigorous screening and testing make sure that quality meets the customers' specifications.

Our extensive plentiful inventory us to offer lowest price most rapid delivery.

Testing polished aluminum plate and international sales team with more than ten years experience will provide you peace of assurance when you make purchase decisions.

We can different resources according customer's you one-stop purchasing polished aluminum plate.Professional processing centers meet the customized needs different customers.