Why are stainless steel pipes a wise option for all applications

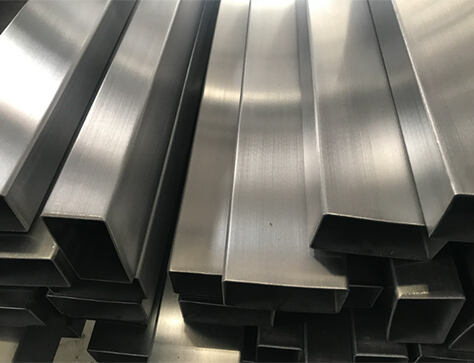

Stainless steel pipes are vital elements utilized in transporting numerous compounds - fluids, gases or perhaps solid materials. These lengthy, silverish tubes are made of stainless steel which is a potent metal that exhibits excellent strength and sturdiness while also being non-corrosive hence making it the undisputed choice for various industrial purposes.

The utility of stainless steel pipes stretches to a great deal when it comes with advantages. One the major advent is their incredible rust resistance, they manage to survive in a variety of conditions without corroding. Stainless steel pipes can be used in residential settings, industrial plants and medical facilities to transport water oil and gas.

Going further into stainless steel pipes we can see that it is available in different grades and shapes. The quality and intake of stainless can have a massage bearing on its power, as well as abshore grades being greater staunch to getting extensive wearing and corrosion than further minimal stanless energies. There is also the matter of what shape the pipe comes in based on application, with some pipes having straight conformity and others bending at an angle. The next chapter is all about how grades and shapes help in choosing the right stainless steel pipe for different types of needs.

For construction and manufacturing, stainless steel pipes are utilized for many reasons. Their strength and durability have proved invaluable in the construction of structures, as well as industrial processes. These durable pipes can take on the extreme wear and tear without failing as they come with an impressive resistance to rust and corrosion which makes them suitable for use in water or damp environments.

How to Keep Stainless Steel Piping for a Long Time

In order to keep your fleet of stainless steel pipes in use for a longer period, you need proper maintenance and care. One of the easiest ways to keep your pipes looking good is simply by keeping them clean with a soft, lint-free cloth. NOTE: Strong cleaners that can damage the surface of pipe should be avoided. The use of stainless steel polish is recommended when it experiences scratches and any other damage which damages the pipes for prolonged functionality.

Welding is the most critical process in stainless steel pipe production. When welding stainless steel pipes, a variety of methods can be used to get them all, and they each have some merits. The Tungsten Inert Gas (TIG) welding method, much probably the most common one relies on a tungsten electrode to heat and melt the metal efficiently combining it in such a way that creates robust joints of high strength. The process allows for faster welding, however, a weaker joint due to the wire and shielding gas.

In simple words, stainless steel pipes are highly precious in different industries with high durability and great corrosion resistance. Understanding grades, shapes, maintenance practices and welding techniques provides one a comprehensive knowledge into the interdisciplinary nature of them.

We can match different stainless steel piperesources according customer's needs give one-stop purchasing .Professional centers meet customized needs different customers.

Our extensive stainless steel pipeinventory allows to provide best price well as fastest delivery.

Each batch goods is examined and tested by a group of experts using most sophisticated stainless steel pipeequipment. ensures that the quality meets customer requirements.

Testing quality a sales team from around world with over ten years' experience give you peace assurance when make your buying stainless steel pipe.