- Overview

- Inquiry

- Related Products

Composition:1050A aluminum alloy primarily consists of aluminum, with a minimum purity of 99.5%. It also contains small amounts of other elements such as iron and silicon.

Strength and Hardness:1050A has relatively low strength compared to other aluminum alloys. It is known for its excellent formability and ductility, making it easy to work with.

Corrosion Resistance:The alloy exhibits good resistance to corrosion, particularly in environments where there is low chemical exposure. However, it may not be suitable for applications in highly corrosive environments.

Weldability:1050A aluminum alloy is highly weldable, allowing for various welding techniques to be used without compromising its properties.

Electrical Conductivity:It has excellent electrical conductivity, making it suitable for applications in electrical conductors and components.

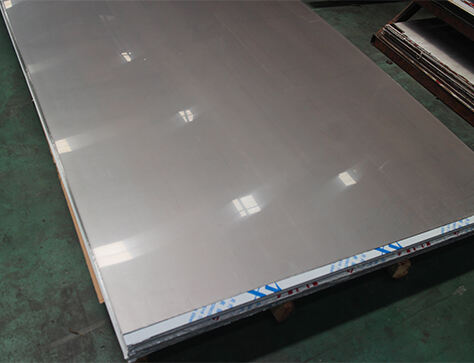

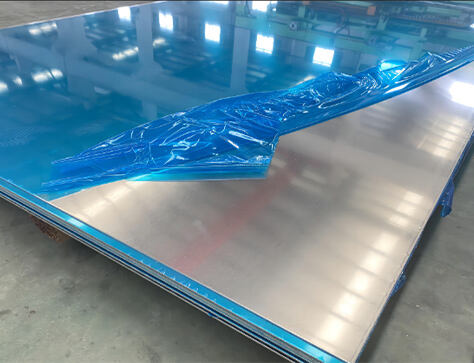

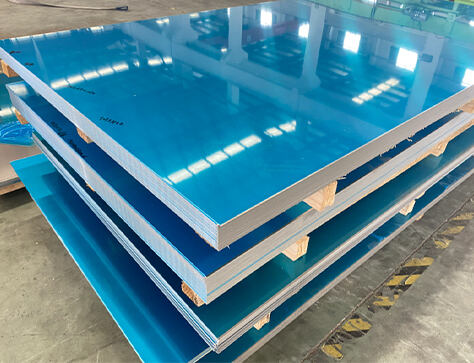

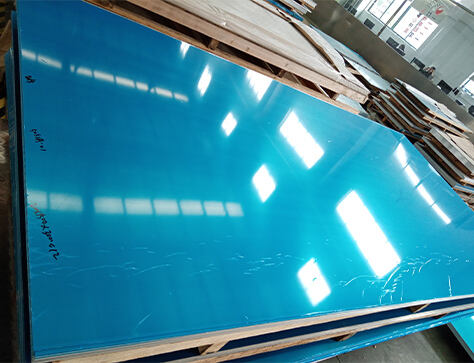

Surface Finish:The alloy can achieve a smooth and attractive surface finish, which is desirable in applications where aesthetics are important.

Heat Treatment:1050A is not heat-treatable, meaning its mechanical properties are not significantly affected by heat treatment processes.

Architectural Applications:Due to its good formability and attractive surface finish, 1050A is commonly used in architectural applications, such as building facades and decorative elements.

Electrical Components:The high electrical conductivity of 1050A makes it suitable for manufacturing electrical conductors, cables, and other electrical components.

Food and Chemical Industry:Its corrosion resistance, particularly in low-chemical environments, makes it suitable for use in the food and chemical processing industries.

General Sheet Metal Work:The alloy's excellent formability and weldability make it a preferred choice for general sheet metal work, where intricate shapes and designs are required.

Reflectors and Heat Exchangers:The reflective properties of aluminum, combined with its thermal conductivity, make 1050A suitable for applications such as reflectors and heat exchangers.

Signage and Nameplates:The alloy's ability to take on a smooth surface finish makes it suitable for signage, nameplates, and other decorative elements.

Description

1050A aluminum alloy is a commercially pure aluminum grade known for its excellent formability and corrosion resistance. Composed mainly of aluminum (99.5% minimum), it also contains trace amounts of iron and silicon. This alloy offers good electrical conductivity, making it suitable for electrical applications. Its low strength makes it ideal for processes like bending, spinning, and stamping. Commonly used in cookware, signage, and general sheet metal work, 1050A is valued for its ease of fabrication and smooth surface finish. Its versatility extends to applications such as reflectors, nameplates, and certain chemical and food processing uses.

| Alloy | Temper |

| 1xxx:1050,1050A,1060,1100 | O,H12,H14,H16,H18,H22,H24,H26,H28,H111 |

| 3xxx:3003,3004,3005,3105 | |

| 5xxx:5005,5052,5754,5083,5086,5182,5049,5251,5454 | O,H22, H24,H26,H28,H32,H34,H36,H38,H111 |

| 6xxx:6061,6082 | T4, T6,T451,T651 |

| 2xxx: 2024 | T3, T351,T4 |

| 7xxx:7075 | T6, T651 |

| Dimension | Range |

| Thickness | 0.5~6.0 mm for sheet 6.0~120 mm for plate |

| Width | 600~2,200 mm |

| Length | 2,000~10,000 mm |

| - Standard Width and Length: 1000x2000 mm, 1250x2500 mm, 1500x3000 mm,1219x2438 mm - Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed - Surface Protection: Paper interleaved, PE/PVC filming (if specified) - Minimum Order Quantity: 3~5MT per size, total 20MT for one order | |

What Are Grade 1050A Properties?

What Are The Applications of 1050A aluminum sheet?

It's important to note that specific applications may vary based on the precise alloy and temper of the 1050A aluminum, as well as the requirements of the intended use.

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

UR

UR

BN

BN

LO

LO

MY

MY