- Overview

- Inquiry

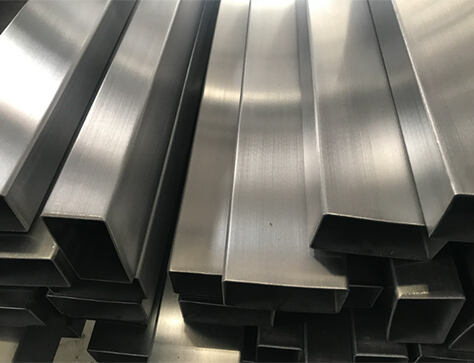

- Related Products

Corrosion Resistance: 3003 aluminum exhibits excellent corrosion resistance, making it suitable for various environments, including marine and industrial applications.

Formability: This alloy has good formability, allowing it to be easily shaped, bent, and formed without compromising its structural integrity. It is commonly used in the manufacturing of intricate parts.

Weldability: 3003 aluminum is weldable using various techniques, such as MIG and TIG welding, enabling the fabrication of complex structures and assemblies.

Strength: While not as strong as some other aluminum alloys, 3003 provides sufficient strength for many applications, particularly when combined with its other favorable properties.

Heat Conductivity: The alloy has moderate heat conductivity, making it suitable for heat exchangers and other applications where thermal properties are important.

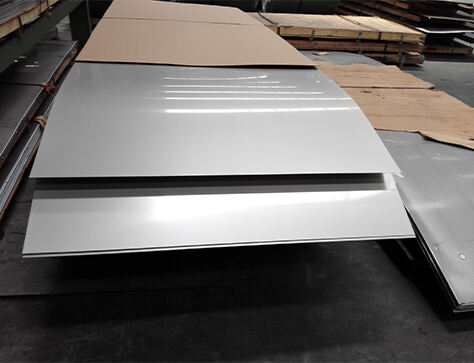

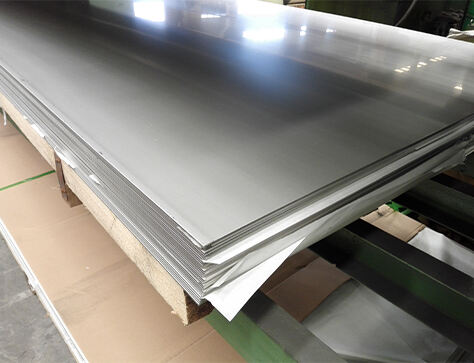

Surface Finish: 3003 aluminum can be easily finished and coated, allowing for a variety of surface treatments such as anodizing, painting, or coating to enhance its appearance and durability.

Cookware and Kitchen Utensils: The formability and corrosion resistance of 3003 aluminum make it a popular choice for the production of cookware, kitchen utensils, and food containers.

Architecture and Construction: Due to its combination of strength, formability, and corrosion resistance, 3003 aluminum is used in construction for roofing, siding, and architectural elements.

Heat Exchangers: The alloy's thermal conductivity makes it suitable for heat exchangers, including those in air conditioning systems and automotive radiators.

Storage Tanks: 3003 aluminum is often used in the construction of storage tanks for liquids, such as fuel tanks and chemical storage tanks, thanks to its corrosion resistance.

General Sheet Metal Work: The easy formability and weldability of 3003 aluminum make it a popular choice for general sheet metal fabrication, including panels and components in various industries.

Trailer Siding: Its combination of strength and corrosion resistance makes 3003 aluminum a suitable material for the siding of trailers and other transportation vehicles.

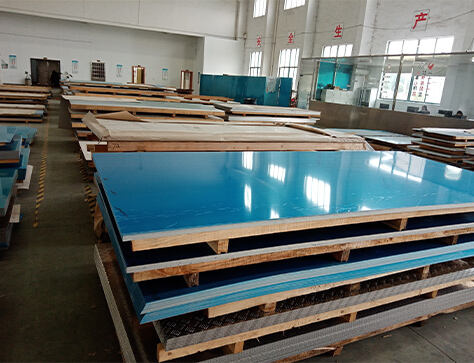

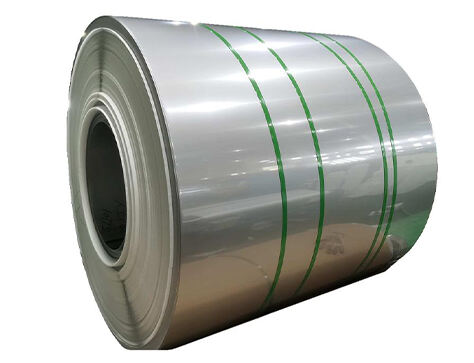

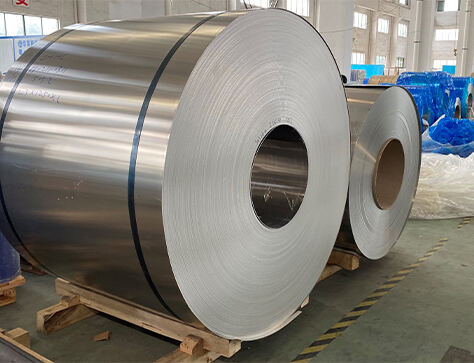

Description

3003 aluminum alloy is a non-heat-treatable alloy with a composition primarily of aluminum, manganese, and a trace amount of copper. Known for its excellent corrosion resistance, it finds applications in general fabrication, food containers, and chemical equipment. With good formability, it is often used for sheet metal work and in products requiring moderate strength and high corrosion resistance.

| Alloy | Temper |

| 1xxx:1050,1050A,1060,1100 | O,H12,H14,H16,H18,H22,H24,H26,H28,H111 |

| 3xxx:3003,3004,3005,3105 | |

| 5xxx:5005,5052,5754,5083,5086,5182,5049,5251,5454 | O,H22, H24,H26,H28,H32,H34,H36,H38,H111 |

| 6xxx:6061,6082 | T4, T6,T451,T651 |

| 2xxx: 2024 | T3, T351,T4 |

| 7xxx:7075 | T6, T651 |

| Dimension | Range |

| Thickness | 0.5~6.0 mm for sheet 6.0~120 mm for plate |

| Width | 600~2,200 mm |

| Length | 2,000~10,000 mm |

| - Standard Width and Length: 1000x2000 mm, 1250x2500 mm, 1500x3000 mm,1219x2438 mm - Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed - Surface Protection: Paper interleaved, PE/PVC filming (if specified) - Minimum Order Quantity: 3~5MT per size, total 20MT for one order | |

Properties of 3003 Aluminum Plate:

Applications of 3003 Aluminum Plate:

In summary, 3003 aluminum alloy is a versatile material with a range of beneficial properties, making it well-suited for applications in various industries, including construction, transportation, and manufacturing.

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

UR

UR

BN

BN

LO

LO

MY

MY