- Overview

- Inquiry

- Related Products

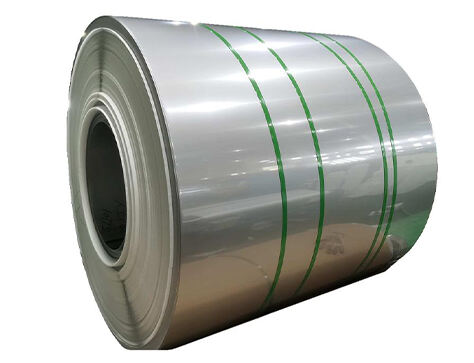

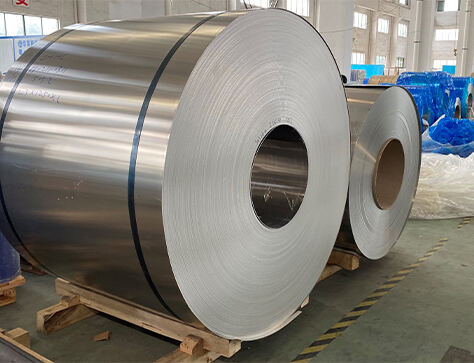

Composition: 1060 aluminum alloy is a pure aluminum alloy with a minimum aluminum content of 99.60%. It belongs to the 1xxx series of aluminum alloys.

Formability: This alloy has excellent formability, making it highly suitable for various forming processes such as rolling, extrusion, and drawing.

Corrosion Resistance: While 1060 aluminum has good corrosion resistance in certain environments, it is not as corrosion-resistant as some other aluminum alloys. It is more prone to corrosion in harsh conditions.

Electrical Conductivity: One of the notable properties of 1060 aluminum is its high electrical conductivity, making it suitable for electrical applications.

Thermal Conductivity: It also has good thermal conductivity, allowing for efficient heat dissipation.

Electrical Industry: Due to its high electrical conductivity, 1060 aluminum is commonly used in electrical applications such as electrical conductors, transformer windings, and capacitors.

Heat Sinks: The alloy's good thermal conductivity makes it suitable for manufacturing heat sinks used in electronic devices to dissipate heat effectively.

Reflectors: The high reflectivity of polished 1060 aluminum makes it suitable for reflective surfaces, such as in lighting fixtures and solar reflectors.

Food and Chemical Handling: 1060 aluminum is used in the food industry for containers and packaging due to its non-toxic properties. It is also suitable for chemical processing equipment.

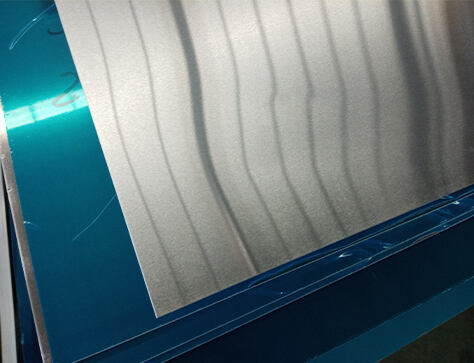

General Sheet Metal Work: Its excellent formability makes 1060 aluminum alloy suitable for general sheet metal work, including roofing, cladding, and other architectural applications.

Description

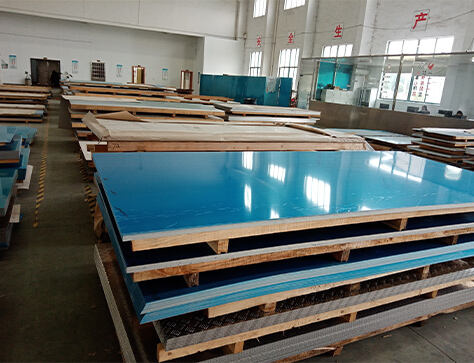

1060 aluminum is a pure commercial-grade alloy with exceptional formability, high electrical conductivity, and good corrosion resistance. Its versatile nature makes it ideal for electrical applications, general sheet metal work, reflectors, signage, heat sinks, and decorative elements in various industries.

| Alloy | Temper |

| 1xxx:1050,1050A,1060,1100 | O,H12,H14,H16,H18,H22,H24,H26,H28,H111 |

| 3xxx:3003,3004,3005,3105 | |

| 5xxx:5005,5052,5754,5083,5086,5182,5049,5251,5454 | O,H22, H24,H26,H28,H32,H34,H36,H38,H111 |

| 6xxx:6061,6082 | T4, T6,T451,T651 |

| 2xxx: 2024 | T3, T351,T4 |

| 7xxx:7075 | T6, T651 |

| Dimension | Range |

| Thickness | 0.5~6.0 mm for sheet 6.0~120 mm for plate |

| Width | 600~2,200 mm |

| Length | 2,000~10,000 mm |

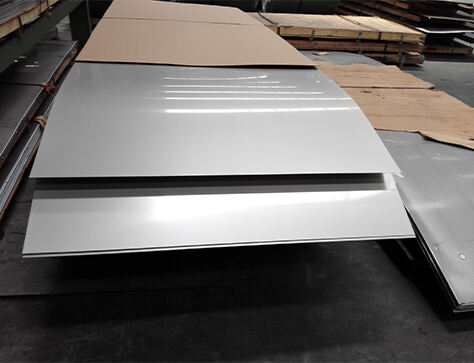

| - Standard Width and Length: 1000x2000 mm, 1250x2500 mm, 1500x3000 mm,1219x2438 mm - Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed - Surface Protection: Paper interleaved, PE/PVC filming (if specified) - Minimum Order Quantity: 3~5MT per size, total 20MT for one order | |

What Are Grade 1060 Properties?

What Are The Applications of 1060 aluminum sheet?

It's important to note that while 1060 aluminum has favorable properties for certain applications, its low strength compared to other alloys might limit its use in high-stress structural applications.

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

UR

UR

BN

BN

LO

LO

MY

MY