- Overview

- Inquiry

- Related Products

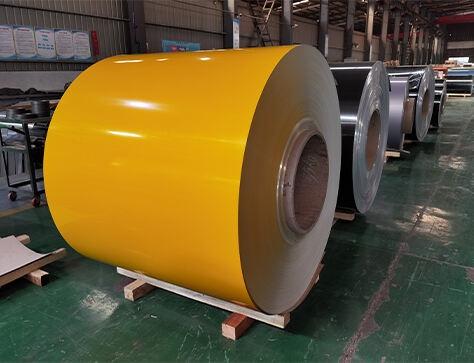

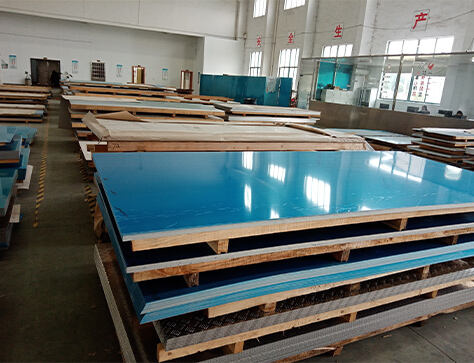

Corrosion Resistance: The aluminum base provides inherent corrosion resistance, while the color coating enhances durability in diverse environments.

Aesthetic Versatility: Color coated aluminum sheets offer a wide range of vibrant colors and finishes, providing flexibility for design and aesthetic preferences.

Weather Resistance: Designed to withstand exposure to harsh weather conditions, making them suitable for outdoor applications.

Formability: The underlying aluminum substrate allows for easy shaping and forming, adapting to various fabrication requirements.

Lightweight: Maintains the lightweight properties of aluminum, facilitating ease of handling, transportation, and installation.

Customization: Easily customizable in terms of color, texture, and patterns to meet specific project needs.

Architectural Cladding: Used for exterior cladding in buildings, offering both protection and an attractive appearance.

Signage and Branding: Ideal for outdoor signage due to its weather-resistant coating and the ability to showcase vibrant colors and logos.

Roofing and Facades: Applied in roofing and facade systems for both residential and commercial structures, providing durability and visual appeal.

Interior Design: Employed for interior decoration, wall panels, and ceilings, enhancing aesthetics in residential and commercial spaces.

Automotive Trim: Utilized in the automotive industry for decorative elements and trim components, combining style and functionality.

Appliance Panels: Used for coating panels in appliances, providing a durable and visually appealing surface.

Furniture Manufacturing: Applied in the production of furniture components, adding a decorative touch to functional pieces.

Description

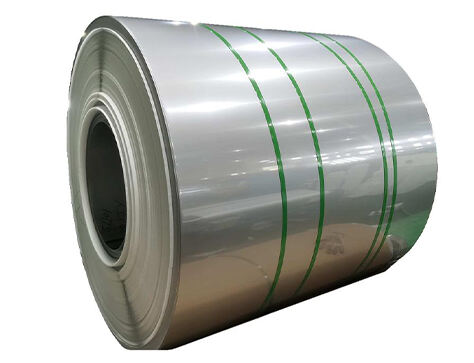

Color coated aluminum sheets are aluminum plates coated with a durable layer of colored paint or coating. This not only enhances aesthetic appeal but also provides additional protection against corrosion. Widely used in architecture, signage, and decorative applications, these sheets offer a vibrant and durable solution for projects requiring both functionality and visual appeal. The color coating process ensures a long-lasting finish, making them ideal for exterior applications where weather resistance is crucial.

| Alloy | Temper |

| 1xxx:1050,1050A,1060,1100 | O,H12,H14,H16,H18,H22,H24,H26,H28,H111 |

| 3xxx:3003,3004,3005,3105 | |

| 5xxx:5005,5052,5754,5083,5086,5182,5049,5251,5454 | O,H22, H24,H26,H28,H32,H34,H36,H38,H111 |

| 6xxx:6061,6082 | T4, T6,T451,T651 |

| 2xxx: 2024 | T3, T351,T4 |

| 7xxx:7075 | T6, T651 |

| Dimension | Range |

| Thickness | 0.5~6.0 mm for sheet 6.0~120 mm for plate |

| Width | 600~2,200 mm |

| Length | 2,000~10,000 mm |

| - Standard Width and Length: 1000x2000 mm, 1250x2500 mm, 1500x3000 mm,1219x2438 mm - Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed - Surface Protection: Paper interleaved, PE/PVC filming (if specified) - Minimum Order Quantity: 3~5MT per size, total 20MT for one order | |

Properties of Color Coated Aluminum Sheet:

Applications of Color Coated Aluminum Sheet:

In summary, color coated aluminum sheets offer a combination of aesthetic appeal, corrosion resistance, and versatility, making them suitable for a wide range of applications in construction, signage, and design.

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

UR

UR

BN

BN

LO

LO

MY

MY