- Overview

- Inquiry

- Related Products

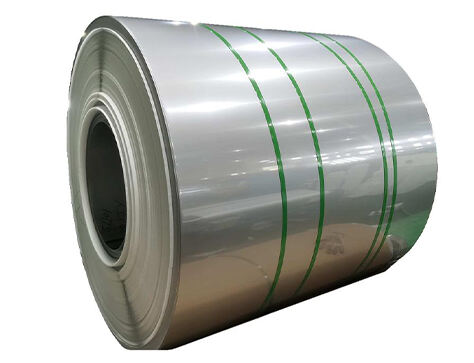

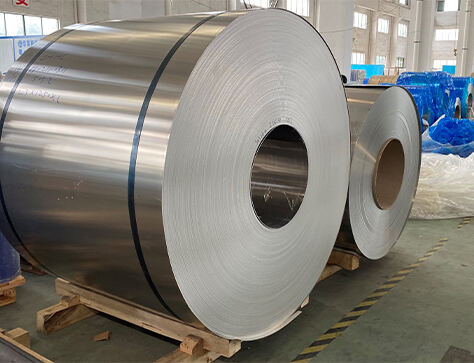

Corrosion Resistance: Galvanized coils and sheets exhibit excellent corrosion resistance, as the zinc layer forms a protective oxide layer that effectively prevents oxidation and corrosion on the steel surface.

Weather Resistance: Due to the presence of the zinc layer, these products demonstrate good weather resistance, making them suitable for both indoor and outdoor environments.

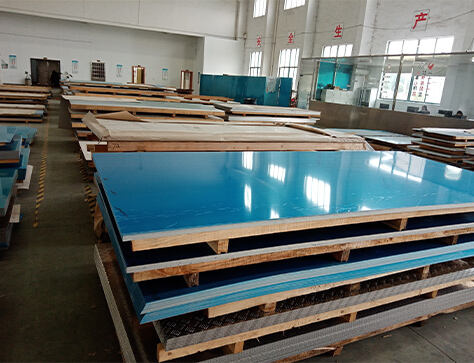

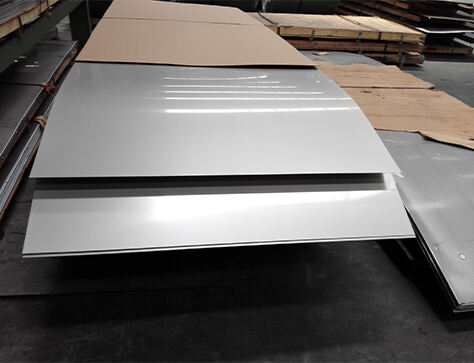

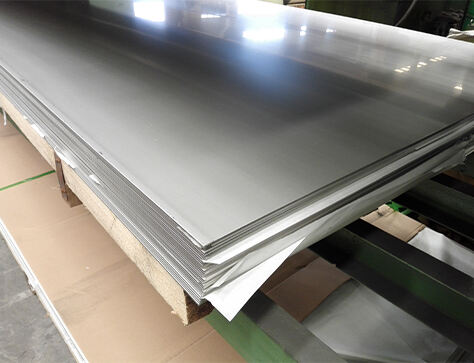

Aesthetic Appeal: The surfaces of galvanized coils and sheets are smooth and possess a metallic luster, contributing to a pleasing aesthetic appearance in construction and decoration.

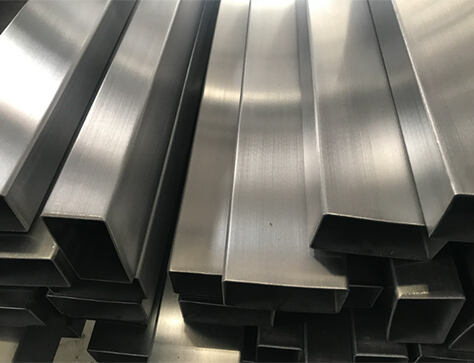

High Ductility: These products have excellent ductility, making them easy to process into various shapes to meet specific requirements in different industries.

Wide Range of Applications: Galvanized coils and sheets are widely used in construction, manufacturing, the automotive industry, and more. In construction, they are utilized for roofing, walls, ventilation ducts, and other structures. In manufacturing, they are used in the production of various equipment and components. In the automotive industry, they are commonly employed in the manufacturing of vehicle body parts.

Description

| Product | Finish | Thickness(mm) | Strip | Width(mm) | ||

| <1000 | 1250 | 1500 | 2000 | |||

| Grade | Spcc Secc Dx51d Dx52d Dx53d | |||||

| Z40Z60Z80Z120Z180Z275 | Zero Spangle,Regualr Spangle,Oiled,Non-oiled, | 0.12≤t≤3.0 | * | * | * | |

| 3.5≤t≤6.0 | * | * | ||||

| 3.0≤t<5.0 | * | * | * | |||

| 5.0≤t≤12 | * | * | ||||

13| * | | |||||

| t>30.0 | Upon Request | |||||

Galvanized coils and sheets are products formed by coating steel surfaces with a layer of zinc. Their characteristics and applications can be categorized as follows:

In summary, galvanized coils and sheets are widely embraced for their outstanding corrosion resistance and versatility, serving as common building and manufacturing materials in various industries.

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

UR

UR

BN

BN

LO

LO

MY

MY