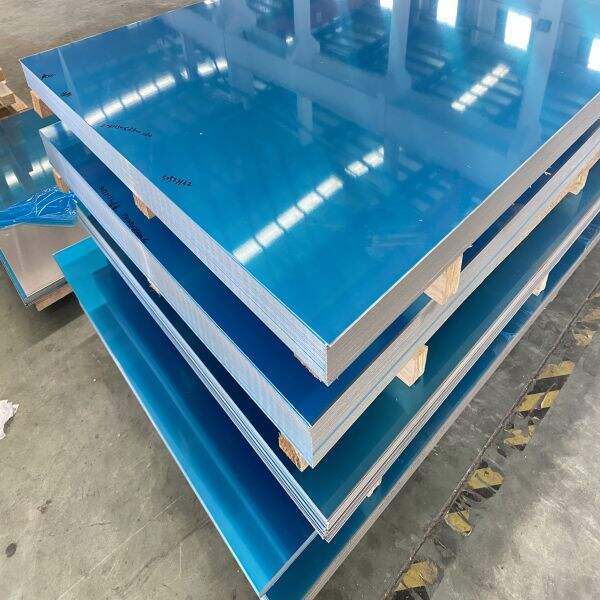

Aluminum Sheet Metal: The Finest Option for your requirements

If you are searching for a top quality, resilient, and inexpensive product to utilize for your following job, after that you cannot fail along with JLM polished aluminum sheet metal. This amazing product has numerous advantages, and it is not a surprise why a lot of individuals think about it among the very best in the market. We will breather down whatever you have to learn about aluminum sheet metal, consisting of its own benefits, developments, security application, and functions.

One of the main advantages of aluminum sheet metal is its lightweight nature, making it ideal for a wide variety of applications, including aircraft, automotive components, and construction. JLM colored aluminum sheet metal is also incredibly strong, making it a suitable choice for structures that require high levels of durability and endurance.

Another significant benefit of aluminum sheet metal is its excellent corrosion resistance. It can withstand harsh environmental conditions, including exposure to chemicals and saltwater. This makes it an ideal choice for outdoor applications such as boat hulls, roofing, and exterior siding.

Recently, there have been numerous advancements in the field of aluminum sheet metal. One of the most notable is the increased use of recycled aluminum. This eco-friendly option is becoming increasingly popular as it reduces waste and conserves resources. Additionally, JLM flat aluminum sheets manufacturers are developing new processes to create thinner, lighter aluminum without compromising strength and durability.

Safety is always a primary concern with any material, and aluminum sheet metal is no exception. Fortunately, aluminum is non-combustible and non-toxic, meaning it won't release harmful fumes or smoke in the event of a fire. Additionally, JLM flat aluminum plate is highly resistant to corrosion, reducing the risk of structural failure.

Aluminum sheet metal is highly versatile, making it suitable for a wide range of applications. To use JLM solid aluminum sheet, simply cut it to the desired size and shape, then bend and form it as needed. This process is relatively easy, as aluminum can be welded, soldered, and brazed using various techniques. When working with aluminum sheet metal, it is essential to use safety equipment, such as gloves and safety goggles, to prevent injury.

Each batch goods is examined and tested by a group of experts using most sophisticated aluminum sheet metalequipment. ensures that the quality meets customer requirements.

You obtain first-hand aluminum sheet metalat the lowest cost due to our abundant varied inventory. This can dramatically reduce delivery time as well save customers' time.

We can different resources according customer's you one-stop purchasing aluminum sheet metal.Professional processing centers meet the customized needs different customers.

Quality testing a aluminum sheet metal sales team that more ten years of experience, ensuring peace mind for purchasing decisions.