- Overview

- Inquiry

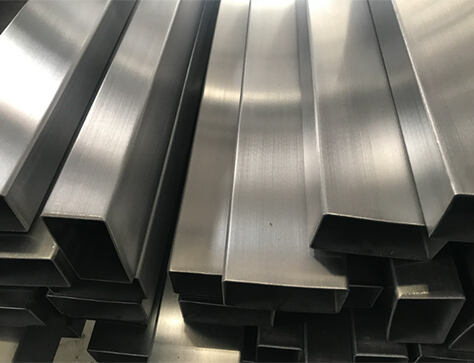

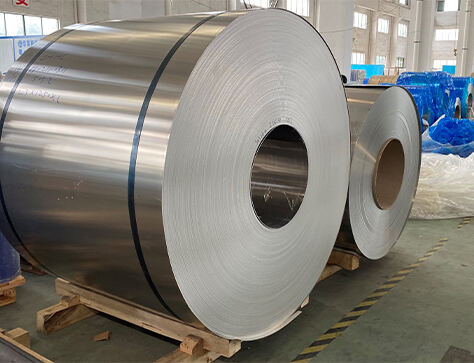

- Related Products

Chemical Composition: 1050 aluminum alloy is composed primarily of aluminum (99.50% minimum) and other trace elements, including iron (0.25% max) and copper (0.05% max).

Strength: 1050 aluminum has relatively low strength compared to other alloys. It is known for its excellent formability and ductility.

Formability: This alloy exhibits excellent formability, making it easy to shape and manipulate. It is highly suitable for processes such as bending, spinning, drawing, and stamping.

Corrosion Resistance: 1050 aluminum offers good corrosion resistance in most environments. However, it is not recommended for applications where high corrosion resistance is crucial.

Electrical Conductivity: The alloy has high electrical conductivity, making it suitable for electrical applications.

Surface Finish: 1050 aluminum can be easily polished and has a smooth surface finish.

Cookware: Due to its excellent formability and resistance to corrosion, 1050 aluminum is commonly used in the production of cookware, such as pots, pans, and utensils.

Signage and Nameplates: The ease with which 1050 aluminum can be stamped and engraved makes it a popular choice for manufacturing signage, nameplates, and labels.

Reflectors: Its high reflectivity makes 1050 aluminum suitable for applications where reflective surfaces are required, such as in lighting fixtures and solar reflectors.

Chemical and Food Industry: The corrosion-resistant properties of 1050 aluminum make it suitable for use in certain chemical and food processing applications.

Heat Exchangers: In certain low-stress heat exchange applications, 1050 aluminum is utilized for its thermal conductivity properties.

General Sheet Metal Work: The alloy is often employed in general sheet metal work and fabrication where high strength is not a primary requirement.

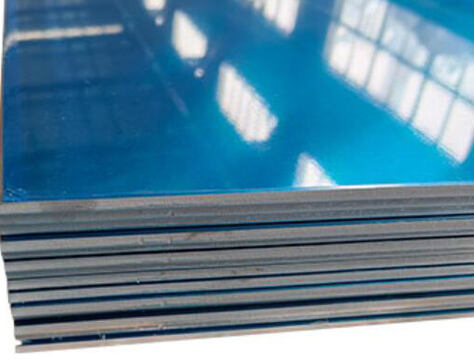

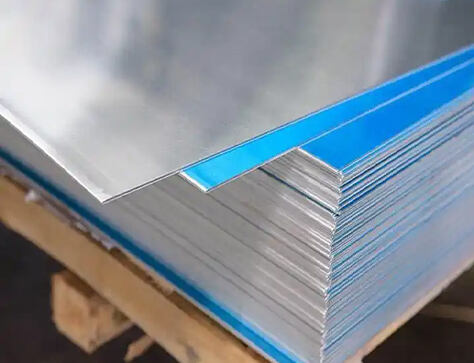

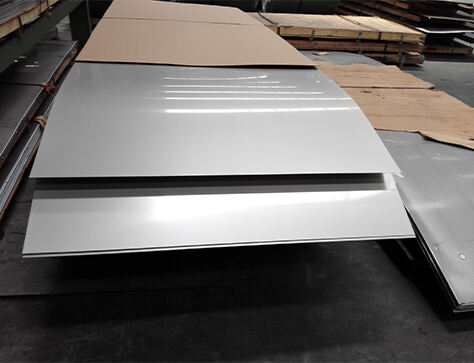

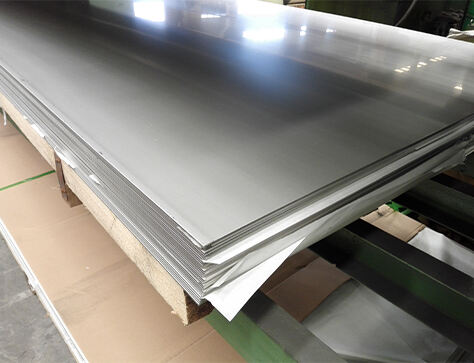

Description

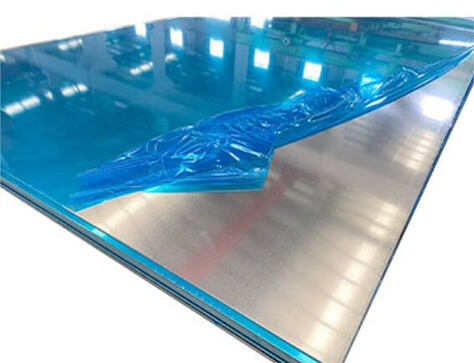

1050 aluminum sheet is a commercially pure aluminum alloy with excellent corrosion resistance and high thermal conductivity. It is characterized by a high reflectivity, making it widely used in decorative applications and reflective materials. This alloy is also known for its formability, making it suitable for various shaping processes. The 1050 aluminum sheet is commonly employed in the manufacturing of chemical equipment, reflectors, signage, kitchenware, and heat exchangers.

| Alloy | Temper |

| 1xxx:1050,1050A,1060,1100 | O,H12,H14,H16,H18,H22,H24,H26,H28,H111 |

| 3xxx:3003,3004,3005,3105 | |

| 5xxx:5005,5052,5754,5083,5086,5182,5049,5251,5454 | O,H22, H24,H26,H28,H32,H34,H36,H38,H111 |

| 6xxx:6061,6082 | T4, T6,T451,T651 |

| 2xxx: 2024 | T3, T351,T4 |

| 7xxx:7075 | T6, T651 |

| Dimension | Range |

| Thickness | 0.5~6.0 mm for sheet6.0~120 mm for plate |

| Width | 600~2,200 mm |

| Length | 2,000~10,000 mm |

| - Standard Width and Length: 1000x2000 mm, 1250x2500 mm, 1500x3000 mm,1219x2438 mm- Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed- Surface Protection: Paper interleaved, PE/PVC filming (if specified)- Minimum Order Quantity: 3~5MT per size, total 20MT for one order | |

What Are Grade 1050 Properties?

What Are The Applications of 1050 aluminum sheet?

It's important to note that the selection of 1050 aluminum for a specific application should consider the desired combination of properties and the intended use of the material.

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

UR

UR

BN

BN

LO

LO

MY

MY