- Overview

- Inquiry

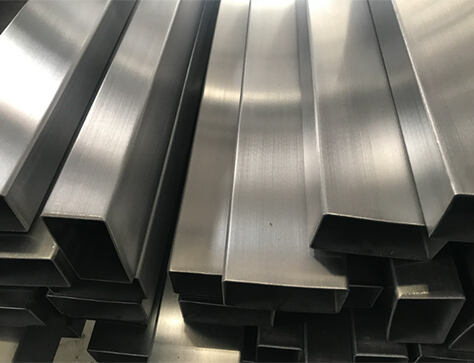

- Related Products

Composition: 1100 aluminum alloy is a commercially pure aluminum with a minimum of 99.0% aluminum content. It is often alloyed with small amounts of other elements, such as copper, manganese, iron, silicon, and zinc.

Malleability: One of the key characteristics of 1100 aluminum is its excellent formability and malleability. It can be easily bent, shaped, and worked into various forms without losing its integrity.

Corrosion Resistance: 1100 aluminum exhibits good resistance to corrosion, making it suitable for applications where exposure to moisture or harsh environmental conditions is a concern.

Corrosion Resistance: 1100 aluminum exhibits good resistance to corrosion, making it suitable for applications where exposure to moisture or harsh environmental conditions is a concern.

Weldability: 1100 aluminum can be welded using various methods, including arc welding and gas welding, making it versatile for manufacturing processes.

Non-Heat-Treatable: 1100 is a non-heat-treatable alloy, meaning its mechanical properties are set during the cooling process after shaping. It cannot be strengthened through heat treatment.

General Fabrication: Due to its excellent formability, 1100 aluminum is commonly used in general fabrication and sheet metal work. It can be easily cut, stamped, and formed into a variety of shapes for different applications.

Food and Chemical Industry: The corrosion resistance of 1100 aluminum makes it suitable for use in equipment and containers for the food and chemical industries where resistance to corrosion is critical.

Reflectors and Decorative Applications: The high reflectivity of polished 1100 aluminum makes it ideal for use in reflective surfaces, such as lighting fixtures, solar reflectors, and decorative elements.

HVAC Systems: 1100 aluminum is utilized in the manufacture of components for heating, ventilation, and air conditioning (HVAC) systems, where its malleability and corrosion resistance are advantageous.

Electrical Applications: Given its reasonable electrical conductivity, 1100 aluminum is employed in electrical conductors, transformer windings, and other applications where lightweight conductivity is essential.

Description

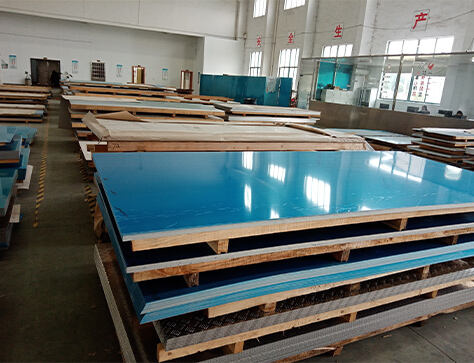

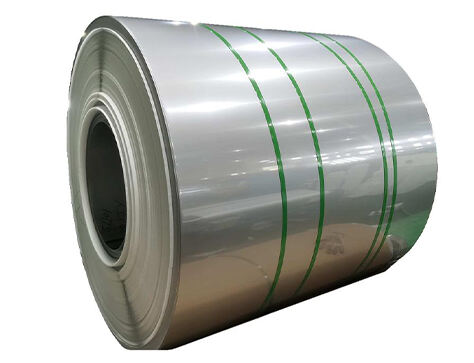

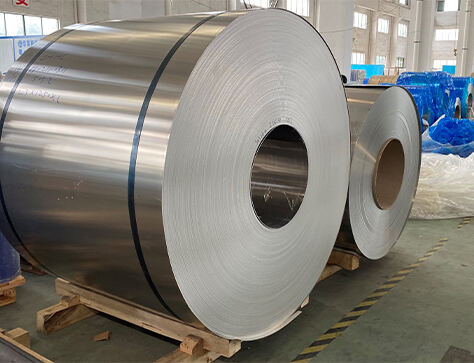

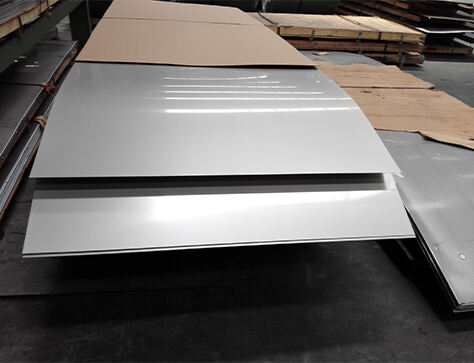

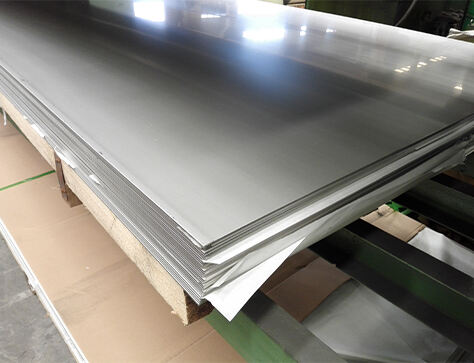

1100 aluminum sheet is a commercially pure alloy, consisting of at least 99.0% aluminum. Known for exceptional formability, it is easily shaped without compromising structural integrity. With good corrosion resistance, weldability, and electrical conductivity, 1100 aluminum finds applications in general fabrication, food and chemical industries, heat exchangers, reflectors, HVAC systems, and electrical components. Its non-heat-treatable nature makes it suitable for various industries where malleability and corrosion resistance are key factors.

| Alloy | Temper |

| 1xxx:1050,1050A,1060,1100 | O,H12,H14,H16,H18,H22,H24,H26,H28,H111 |

| 3xxx:3003,3004,3005,3105 | |

| 5xxx:5005,5052,5754,5083,5086,5182,5049,5251,5454 | O,H22, H24,H26,H28,H32,H34,H36,H38,H111 |

| 6xxx:6061,6082 | T4, T6,T451,T651 |

| 2xxx: 2024 | T3, T351,T4 |

| 7xxx:7075 | T6, T651 |

| Dimension | Range |

| Thickness | 0.5~6.0 mm for sheet 6.0~120 mm for plate |

| Width | 600~2,200 mm |

| Length | 2,000~10,000 mm |

| - Standard Width and Length: 1000x2000 mm, 1250x2500 mm, 1500x3000 mm,1219x2438 mm - Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed - Surface Protection: Paper interleaved, PE/PVC filming (if specified) - Minimum Order Quantity: 3~5MT per size, total 20MT for one order | |

Properties of 1100 Aluminum Alloy:

Applications of 1100 Aluminum Alloy:

It's important to note that the specific application of 1100 aluminum can vary depending on the industry and requirements of the end product.

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

UR

UR

BN

BN

LO

LO

MY

MY