- Overview

- Inquiry

- Related Products

Corrosion Resistance: 3005 aluminum exhibits exceptional corrosion resistance, making it suitable for applications in various environments.

Formability: This alloy has excellent formability, allowing it to be easily shaped, bent, and stamped for diverse manufacturing needs.

Weldability: 3005 aluminum is weldable using different techniques, facilitating the fabrication of complex structures and assemblies.

Strength: While not the highest strength aluminum alloy, 3005 provides satisfactory strength for applications where durability is essential.

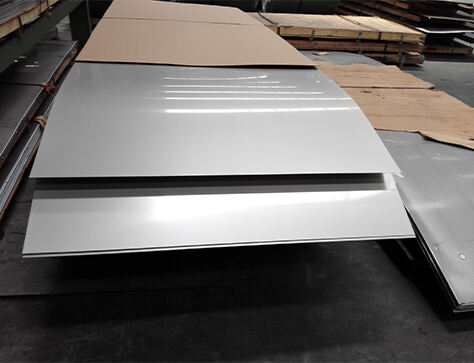

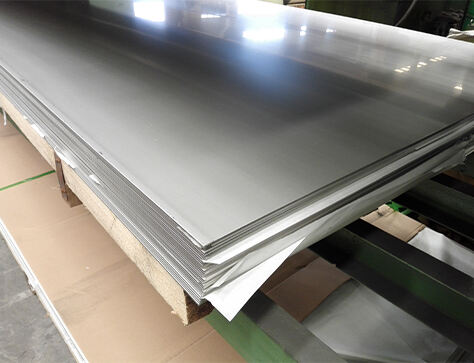

Surface Finish: The alloy can be finished and coated easily, enabling a variety of surface treatments such as painting or coating for enhanced aesthetics and protection.

Building and Construction: 3005 is commonly used in architectural applications, including roofing, siding, and decorative elements, benefiting from its corrosion resistance and formability.

Food and Beverage Packaging: Its excellent corrosion resistance makes 3005 suitable for manufacturing food and beverage containers, ensuring the integrity of stored products.

Automotive Components: The alloy's formability and weldability make it a choice material for manufacturing automotive parts and panels.

General Sheet Metal Work: 3005 aluminum is widely used in various sheet metal applications, where a combination of corrosion resistance and formability is crucial.

Heat Exchangers: Due to its good thermal conductivity, 3005 aluminum is employed in heat exchangers for efficient heat transfer in various industrial and HVAC systems.

Description

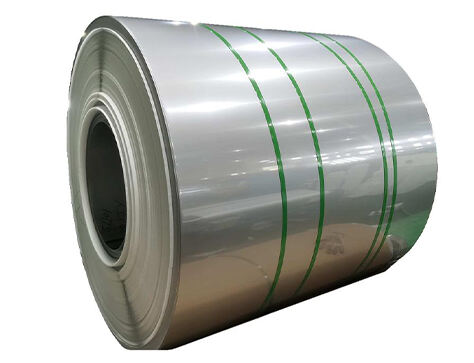

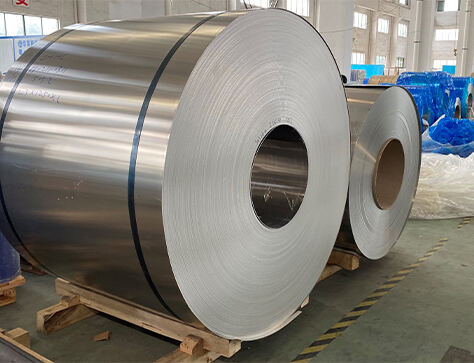

3005 aluminum alloy is a versatile material known for its excellent corrosion resistance and high formability. It finds widespread use in the manufacturing of automotive components, building facades, and general sheet metal applications. With good weldability and surface finish capabilities, 3005 aluminum is a reliable choice for various industries requiring a combination of strength and malleability.

| Alloy | Temper |

| 1xxx:1050,1050A,1060,1100 | O,H12,H14,H16,H18,H22,H24,H26,H28,H111 |

| 3xxx:3003,3004,3005,3105 | |

| 5xxx:5005,5052,5754,5083,5086,5182,5049,5251,5454 | O,H22, H24,H26,H28,H32,H34,H36,H38,H111 |

| 6xxx:6061,6082 | T4, T6,T451,T651 |

| 2xxx: 2024 | T3, T351,T4 |

| 7xxx:7075 | T6, T651 |

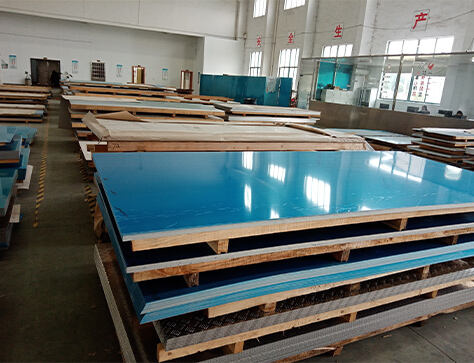

| Dimension | Range |

| Thickness | 0.5~6.0 mm for sheet 6.0~120 mm for plate |

| Width | 600~2,200 mm |

| Length | 2,000~10,000 mm |

| - Standard Width and Length: 1000x2000 mm, 1250x2500 mm, 1500x3000 mm,1219x2438 mm - Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed - Surface Protection: Paper interleaved, PE/PVC filming (if specified) - Minimum Order Quantity: 3~5MT per size, total 20MT for one order | |

Properties of 3005 Aluminum Plate:

Applications of 3005 Aluminum Plate:

In summary, 3005 aluminum alloy is valued for its corrosion resistance, formability, and versatility, making it a preferred choice for applications ranging from construction to food packaging and automotive manufacturing.

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

UR

UR

BN

BN

LO

LO

MY

MY